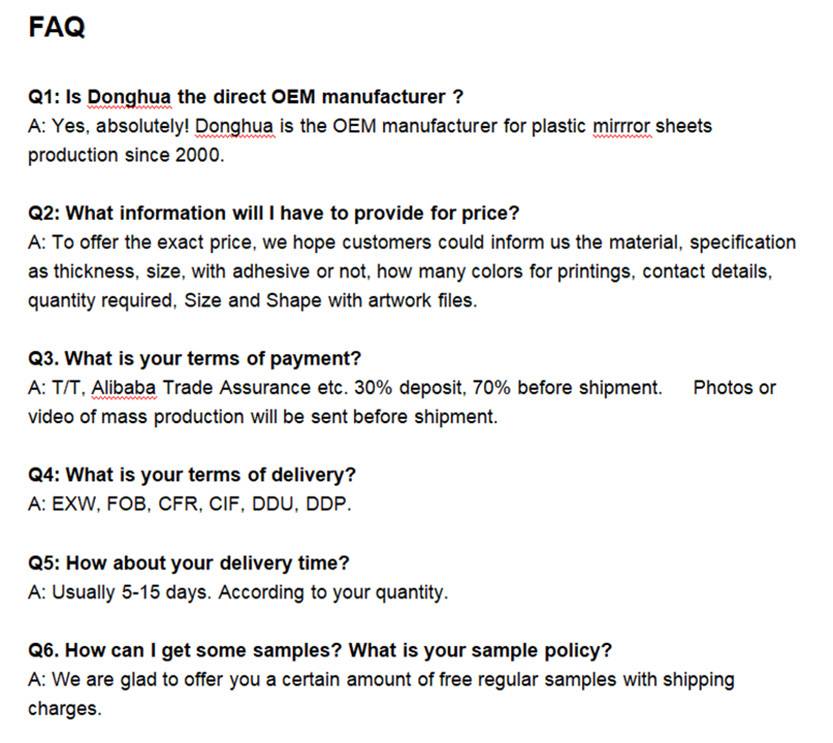

Clear Acrylic Plexiglass Mirror Sheet

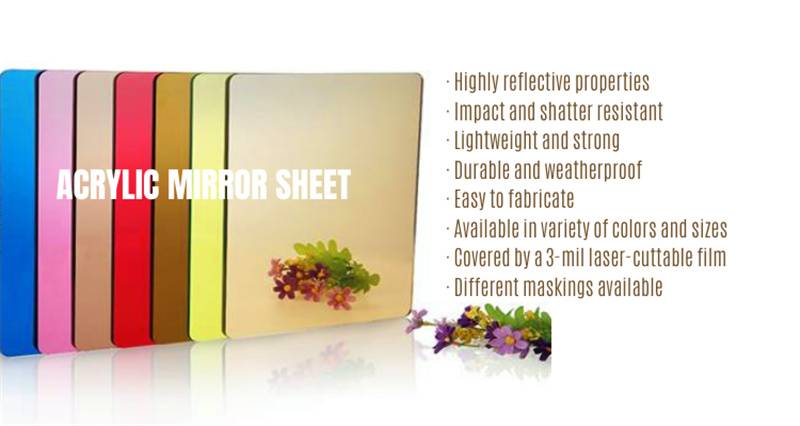

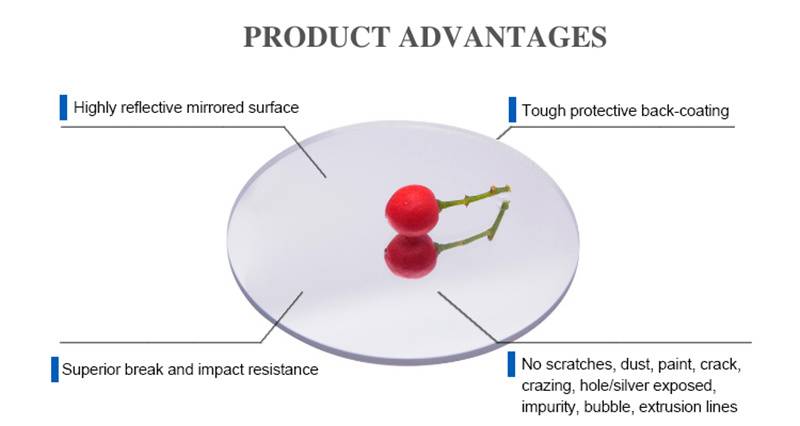

Benefiting from being lightweight, impact, shatter-resistant, less expensive and more durable than glass, our acrylic mirror sheets can be used as an alternative to traditional glass mirrors for many applications and industries. Like all acrylics, our acrylic mirror sheets can be easily cut, drilled, formed fabricated and laser etched.

• Available in 48″ x 72″ / 48″ x 96″ (1220*1830mm/1220x2440mm) sheets; custom sizes available

• Available in .039″ to .236″ (1.0 – 6.0 mm) thicknesses

• 3-mil laser-cut film supplied

• AR scratch-resistant coating option available

Benefiting from being lightweight, impact, shatter-resistant, less expensive and more durable than glass, our acrylic mirror sheets can be used as an alternative to traditional glass mirrors for many applications and industries. Like all acrylics, our acrylic mirror sheets can be easily cut, drilled, formed fabricated and laser etched. Our mirror sheets come in a variety of colors, thicknesses and sizes, and we offer cut-to-size mirror options.

| Product name | Clear acrylic plexiglass mirror sheet |

| Material | Virgin PMMA material |

| Surface Finish | Glossy |

| Color | Clear, silver |

| Size | 1220*2440 mm, 1220*1830 mm, custom cut-to-size |

| Thickness | 1-6 mm |

| Density | 1.2 g/cm3 |

| Masking | Film or kraft paper |

| Application | Decoration, advertising, display, crafts, cosmetics, security, etc. |

| MOQ | 50 sheets |

| Sample time | 1-3 days |

| Delivery time | 10-20 days after getting deposit |

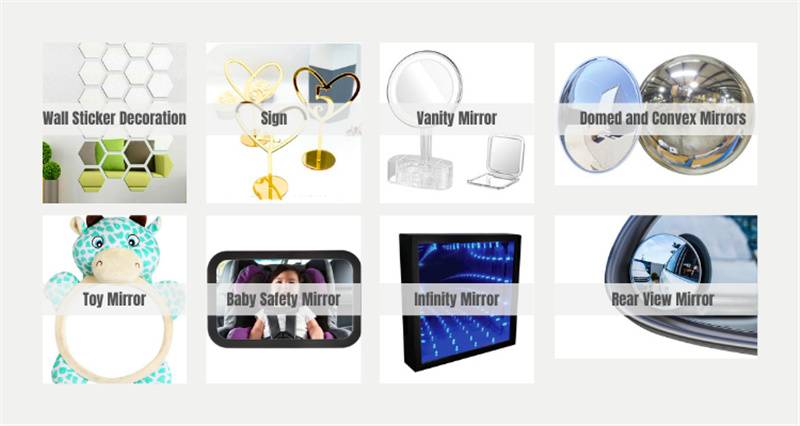

Application

Our acrylic mirror sheets are suitable for a wide range of applications. There are many common uses, with the most popular being Point of sale/Point of purchase, retail display, signage, security, cosmetics, marine, and automotive projects, as well as decorative furniture and cabinet making, display cases, POP/retail/store fixtures, decorative and interior design and DIY projects applications.

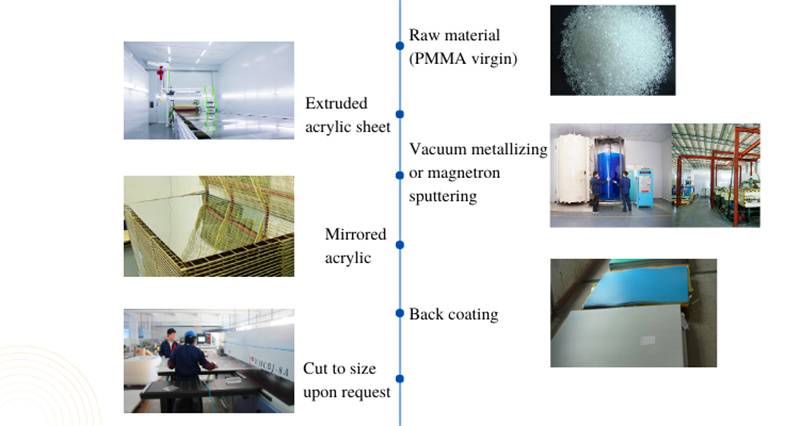

Production Process

Dhua Acrylic Mirror Sheet is made with extruded acrylic sheet. Mirrorizing is done by the process of vacuum metallizing with aluminum being the primary metal evaporated.

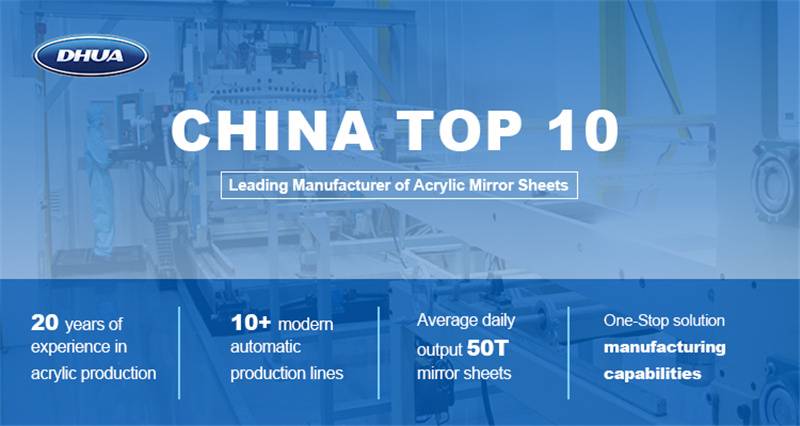

We Are a Professional Manufacturer